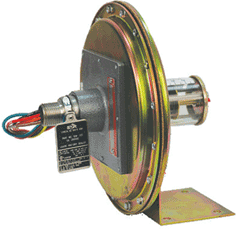

Built to high-quality standards for reliability, this detector is suitable for draft ranges commonlyassociated with HVAC applications and burnermanagement systems. It is also suited for otherindustrial air and gas services which arecompatible with the wetted parts. Standardmodels are available for weathertight orexplosionproofenvironments.

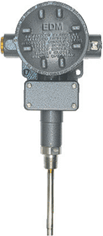

EDM mechanical level detectors are rugged, industrial products specifically designed for versatility of application. This catalog contains application and ordering data for float and displacer-operated level switches. Detectors areavailable with flanged or sealed chambers or as insertion models.

Options available for each type of detector include: switch type and number, housing type, chamber material, process connections,accessories, and more.Units may be customized to suit customers' needs.

Are rugged, field-mounted instruments. The pressure sensing element of the EDM pressure detector is a force-balance, piston-actuated assembly. The sensing element is sealed by a flexible diaphragm and a static o-ring. A wide selection of wetted parts materials for media compatibility and containment are available. A metal diaphragm may be welded to the pressure port for certain applications, thereby eliminating the o-ring.

The EDM temperature detectors utilize a vapor-pressure thermal system. Fluid vapor pressure changes predictably according to the influence of temperature on the sensing bulb. Process temperature changes cause proportional vapor pressure changes in the temperature sensing bulb that act on the diaphragm/piston assembly to actuate and deactuate a snap-action electrical switching element at discrete processtemperatures. The instrument's behavior is determined by the vapor pressure principle.